Typically we use solid rollers for inertial dynamometers, specially for Motorcycle dynamometers due to its extreme simplicity. They can be used for car dynamometers although the amount of steel to be removed to create longer axles (in order to connect each side roller) may be a bit high, which makes more time and money costly the task of creating those axles

Advantages of solid rollers:

- they don’t need dynamic balancing in most cases

- they are easier to build (despite the amount of job to machine de axles)

- they are easy to calculate. Using our spreadsheet you can get the inertia (MOI) using only the diameter and width (without axles)

Disadvantages of solid rollers:

- They are normally heavier than hollow rollers, but only 1/2 of the mass works as inertia, While a hollow roller normally is in the 85% to 90% range.

- They need more amount of steel, although it is not specially expensive compared with the additional tasks to build and balance a hollow roller

- Normally they have short axles, which makes more difficult to add extra parts: disk brakes, couplers for a future brake, etc

Inertia (MOI) calculation:

MOI = (Diameter/2) ^4 * PI (3,1416) * Lenght (m) * ρ (density of steel = 7900 kg*m3) / 2 (ALL sizes in METERS!)

For instance for a 320D x 480W roller, MOI = (0.320/2)^4 * 3.1416 * 0.480 (m) * 7900/2 = 3.9 kg*m2

And weight (not used for power calculation) = (Diameter/2)^2 * PI * Length (m) * ρ (density of steel) = (0.320/2)^2 * 3.1416 * 0.480 * 7900 = 304.9 kg (without axles)

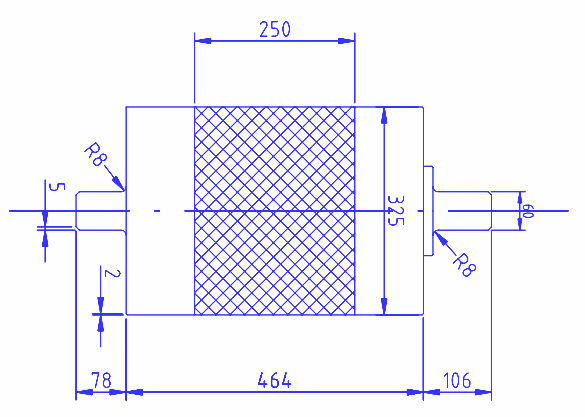

Roller example:

http://www.sportdevices.com/download/plans/Dyno325roller.pdf

Spreadsheet for calculations:

http://www.sportdevices.com/download/rollerssheet.xls