What does SP5 kit include?

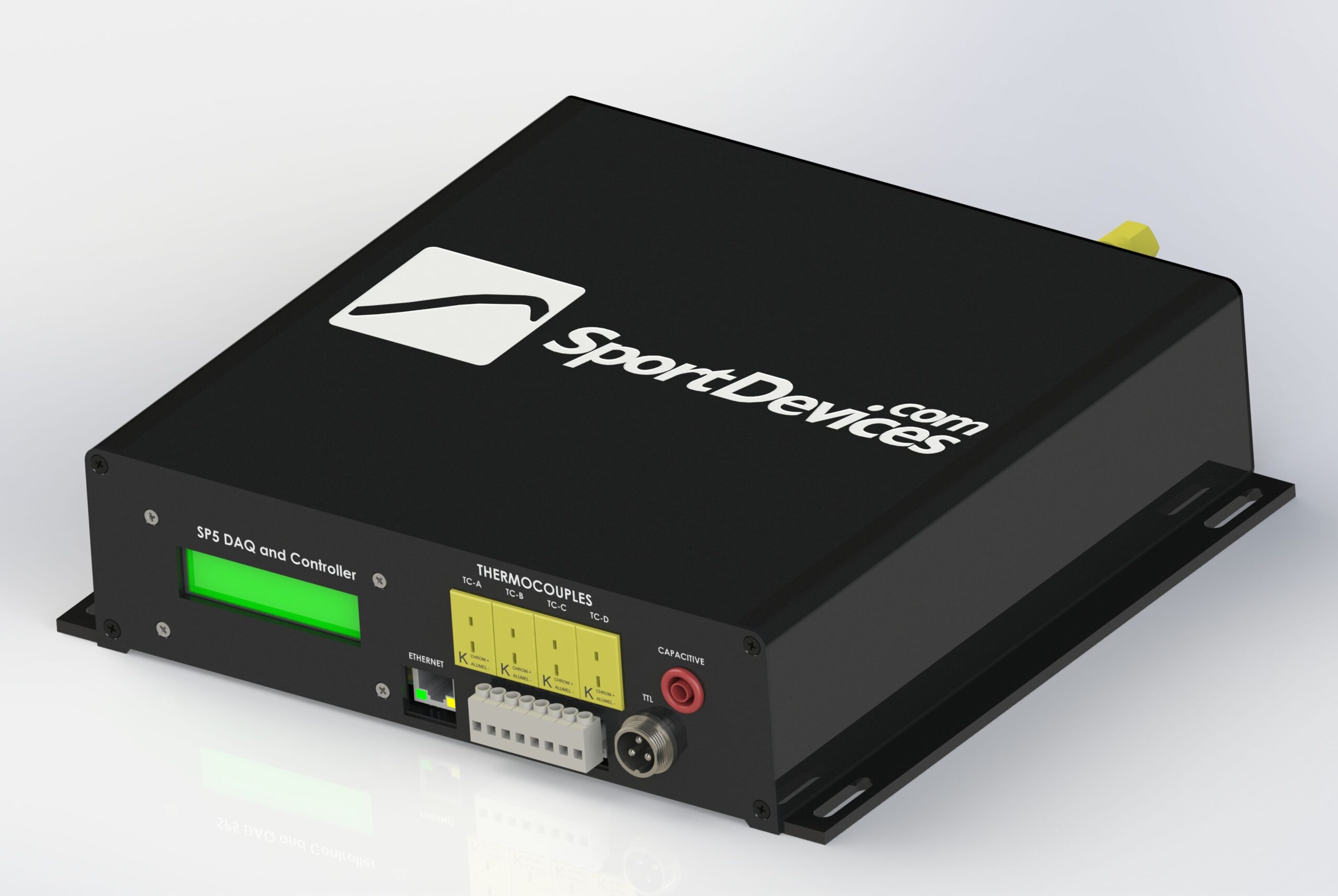

- 1 x SP5 Data Aquisition unit

- 1 x Hall Sensor, for roller / brake speed

- 1 x Capacitive and Inductive clamps, for Engine RPM

- 1 x Load Cell (several sizes available, see below)

- 1 x Brake Power Supply (several voltages and currents available, see below)

- 1 x SP5 to PWS cable adapter

- 1 x Installation cables: Hall sensor extension, Serial Cable

- 1 x USB to Serial adapter, with FTDI chip for the best compatibility

- 1 x Geartooth and braket (new)

AWD Version:

- AWD sync FW activation

- 2nd Hall Sensor, for roller / brake speed

- 2nd Load Cell

- 2nd Brake Power Supply

What SP5 Kit does NOT include?

- Other sensors apart from hall and load cell: Lambda, Weather Station, Pressure sensors, etc

- Other Interfaces: OBDII, xDS (SDS, HDS, KDS)

- Roller

- Eddy current brake

- Relays

- Cooling Fans

- VFDs (Variable Frequency Drive)

- Dyno frame